Sunflower Oil Press

Sunflower Oil Press Introduction

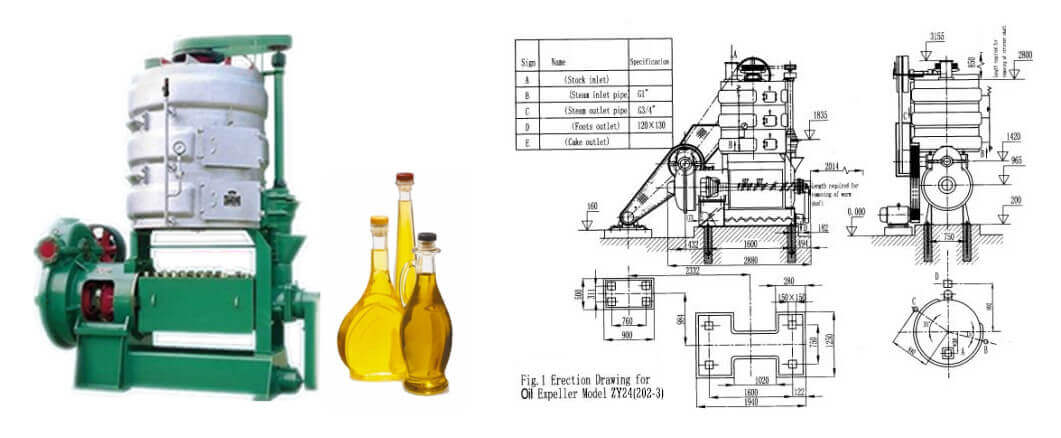

The professional sunflower seed oil mill is ZY24(202-3) continuous oil extraction machine. In small and medium-sized vegetable oil plant, ZY24(202-3) continuous pre-pressing machine is a popular equipment for pre-squeezing and leaching process. ZY24(202-3) pre-pressing machine, which is redesigned on the basis of the 202 pre-pressing machine, has advantages of the reasonable transmission gear, compact structure, and small footprint. And the machine has achieved improvements in the aspects of steaming, dehydrating, uniform feeding, mechanical wringing, and squeezing cage loading and unloading.

Features of ZY24(202-3) Pressing Machine

ZY24(202-3) pressing machine's characteristics have suited to pre-press sunflower seed oil. Under normal pre-pressing conditions, its features are:

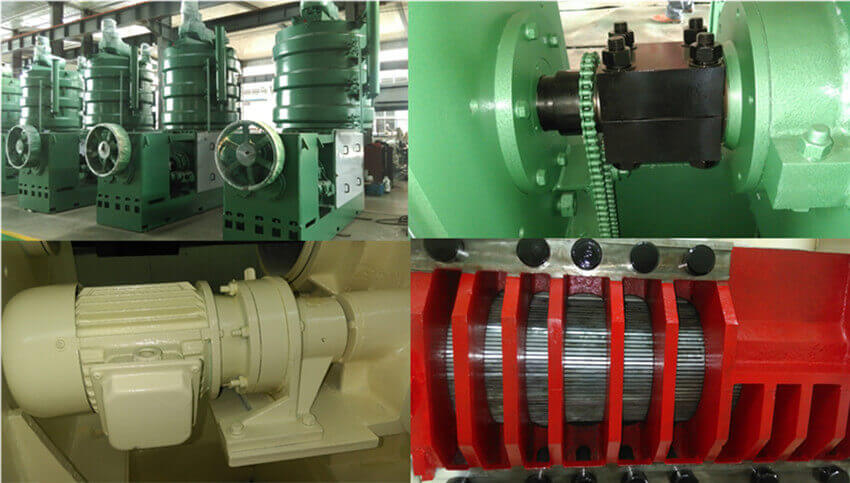

- The machine is made up of stainless steel. The use of high-quality steel carburizing heat treatment can greatly extend the service life of the equipment.

- Large capacity, small workshop area, low power consumption, less operation management and maintenance work.

- The structure of the pre-squeezed cake is loosened but not crushed, which is favorable for the solvent to permeate when leaching; And the oil content and water content of the squeezed cake are suitable for solvent extraction.

- The quality of squeezed oil is better than that of squeezing or leaching once.

Sunflower Oil Squeezing Mill Application

- The pre-pressing machine has a wide range of applications that it can be used to squeeze a variety of oilseed source crop, such as rapeseed, peanuts, cottonseed kernels, sunflower seeds and so on.

- The machine can be used alone as oil pre-pressing equipment or it can be used for twice pressing in the oilseed pretreatment production line with other equipment according to customer needs, and we will choose the right model to the customer.

- With special design, online installation instructions and after sales service, our sunflower seed pre-pressing machine has exported to Southeast Asia, Africa and other countries and regions.

Main Structures of ZY24(202-3) Sunflower Seed Oil Mill

ZY24(202-3) type pre-squeezing machine is made up of the following main components: steamer, feeding mechanism, squeezing cage, squeezing screw shaft (including the cake adjustment mechanism) and transmission.

1. Steamer

This equipment is a vertical three-tier steamer, similar to a typical vertical auxiliary steamer, mounted on a bracket of the frame. Its drive motor is included in the total driveline and steaming can adjust the temperature and moisture of the raw material before it enters the press chamber so that it reaches the requirement of pressing.

2. Feeding Mechanism

The working part of the feeding mechanism is between the discharge port of the steamer and the feeding end of the squeezing shaft. It consists of the squeezing shaft with screw blades at the lower end and the falling cylinder. The entrance of the cylinder has a rotary control valve for controlling the falling flow. There is a hopper under the valve, from which the falling conditions can be observed and the material could be taken out as samples during pressing.

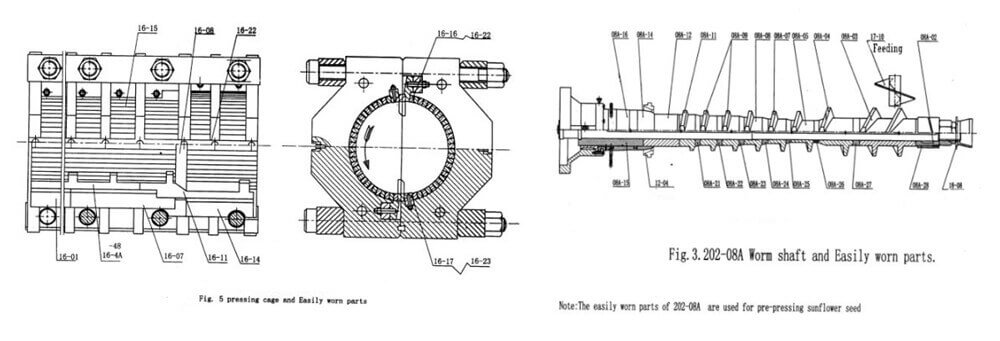

3. Squeezing Cage and Squeezing Screw Shaft

The squeezing cage and squeezing screw shaft are the main components of this equipment. Firstly, the material is pressed down by the feeding mechanism and continuously enters into the space between the squeezing cage & the squeezing screw shaft (called squeezing chamber). Due to the rotation of the squeezing screw shaft and the squeezing chamber gradually reduce the gap, the material is under intense pressure and most of which is pressed out of oil, next, the oil would flow out through the gap of squeeze cage.

Please note: the discharge port of squeeze screw shaft has cake adjustment mechanism to adjust the cake thickness. It consists of some screw thread, fastening flat key, sliding keyway, and other components.

Technical Data of Sunflower Oil Screw Pre-pressing Machine

| Model | ZY24(202-3) |

| Capacity | 40-50 tons/day |

| Dry cake residual oil rate | 14-18% |

| Press shaft speed | 15r/min |

| Motor power | 30KW |

| Dimension | 2900×850×640(mm) |

| Weight | 5500 (kg) |