Soybean Oil Production Line

How to Make Soybean Oil from Soybean Seeds

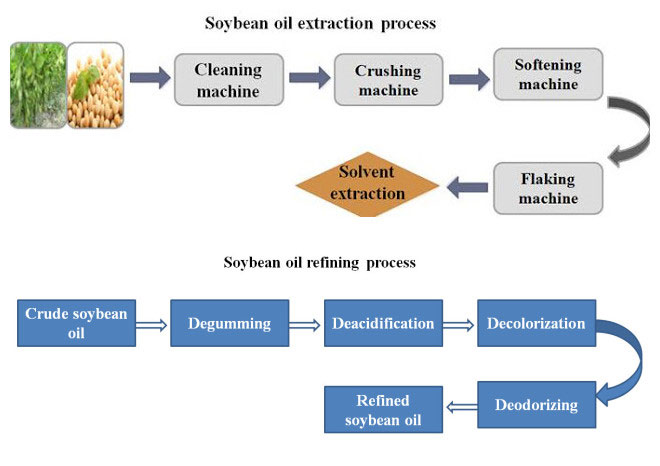

Soybean is a kind of low oil content oilseed compared with other oilseeds such as peanut, sesame, canola, etc. So usually we adopt pretreatment and solvent extraction way to process soybean and get soybean oil, which can reduce residue oil rate and increase oil productivity compared with pressing way. Different oilseeds have different processing technology. Soybean oil production line includes soybean pretreatment process, soybean oil extracting process and soybean crude oil refining process.

Pretreatment Process

Soybean Pretreatment Process

Soybean Cleaning Equipment

High efficiency vibrating screen is adopted here to remove the impurities, so as to effectively achieve the cleaning effect, ensure good operating environment and stability of production, and simultaneously improve the product quality. Suction-type specific gravity stoner is used for removing the mud and stones which have the same size as soybean. The unpowered magnetic selector is applied for removing the iron, and also dust remover is equipped in this process.

Soybean Crushing

In order to achieve the good softening and flaking effect, the soybean needs to be crushed into 4-6 pieces to ensure the uniform granularity. Therefore, when softening, the moisture is uniform and thoroughly. And the flake piece is thin but strong when flaking. The common cracking equipment is roll crusher, hammer crusher and disc huller.

Soybean Softening Machine

The horizontal softening machine is adopted here to heat the soybean to 50-70℃. Therefore, the plasticity of soybean is increased through adjusting the moisture and temperature, creating good operation condition for flaking and cooking. The softening process can not only make the flake become thin, uniform and tough, but reduce the nonhydratable phospholipids content in crude oil, which is convenient for the dephosphorization and physical refining of salad oil.

Soybean Flaking

The cytoderm of soybean is destroyed in this process, meanwhile, the crushed soybean with a certain granularity is made into thin slices with the thickness of 0.3mm, which aims at extracting the maximum oil in the shortest time. Thereby, the extraction speed and rate are increased, and the residual oil in soybean meals is <1%.

Drying

Generally, the flake made from flaking roll has the water content of 12%. However, the optimum moisture for leaching process is 9%, so an effective drying is necessary to achieve the best leaching moisture.

Generally, the flake made from flaking roll has the water content of 12%. However, the optimum moisture for leaching process is 9%, so an effective drying is necessary to achieve the best leaching moisture.

Solvent Extracting Process

Soybean Oil Solvent Extracting Process

The pretreated soybean flakes are sent to the soybean solvent extraction plant. The plant uses a kind of solvent (normal hexane) to absorb the oil from soybean, and then the machines separate the solvent from soybean crude oil. The solvent is used for recycling and soybean crude oil is refined by oil refinery plant.

Features of Soybean Oil Solvent Extracting Technology

- High oil yield. Residual oil in soybean meals is <1%.

- The soybean meal is of good quality.

- Low processing cost and low labor strength.

Soybean Oil Extracting Device Classification

- Immersion Extraction: pot groups extractor, U-type ball extractor, and Y-type extractor

- Percolation Extraction: screen belt type solvent extractor

- Combined Extraction: rotocel extractor, loop type extractor

Refining Process

Soybean Oil Refining Process

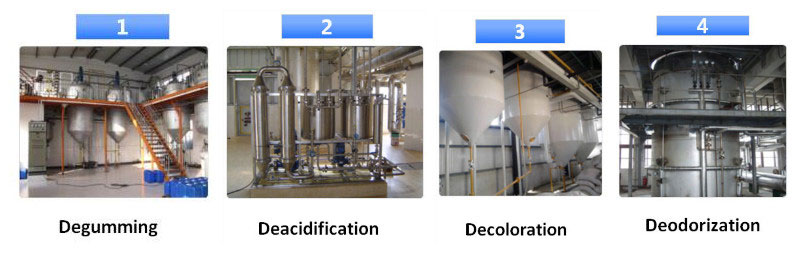

Hydrated Degumming

Take advantage of the hydrophilic group contained in the molecule of phospholipid and other lipoid, add a certain amount of hot water and dilute acids, alkalis, salts and other electrolyte aqueous solutions into the oil, the colloidal impurity will swell and cohere due to water absorption, thus separating out from the soybean oil.

Alkali Refining Deacidifying

Kalify can react with the free fatty acid in grease to form fatty acid salt (soap) and water. Part of impurities is absorbed by soap and then separated out from the oil.

Adsorbing Decoloration

Pigment and other impurities in grease are absorbed by the adsorbent, then adsorbent and impurities are removed by filtration, achieving the decolorization and purification. Adsorbing decoloration is the most widely used decoloring method. Besides, there are also methods of heating decolorization, oxidation decolorization, chemical reagents decolorization, etc.

Vacuum Deodorization

As the last process for the soybean oil processing plant, deodorization aims at removing the substance that causes odors in soybean oil.

Soybean Oil Production Line Advantages

1. Perfect cleaning process: 99% impurities contained in the soybean can be removed in this process, thus reducing the mechanical wear and ensuring the soybean quality.

2. Accurate flaking technology: Cell tissue of soybean is destroyed. Therefore, the surface area is increased and the trip for oil flowing is shortened, which is beneficial to extract the oil and improve the cooking effect.

3. Environmental protection and energy-saving extracting system: Unique exhaust system, better absorption effect, sufficient energy saving design, multiple uses of heat energy, thereby, the steam consumption is saved.

Soybean and Soybean Oil

Soybean is valued for its high protein content (38-45%)) as well as its oil content (approximately 20%). Soybean oil is a vegetable oil extracted from the seeds of soybean, which has a mild nutty flavor and a better texture. It is one of the most widely consumed cooking oils, constituting about half of worldwide edible vegetable oil production. As a semi-drying oil, processed soybean oil is also used as a base for printing inks and oil paints. Thus soybean oil production line is installed worldwide.

REQUEST A QUOTE

You can fill out the following form for your information needs, our technical and commercial staff will contact you. To ensure timely processing of your information, please be sure to accurately complete your contact telephone number.