Small Scale Edible Oil Refinery Plant

Small Scale Edible Oil Refinery Equipment Plant

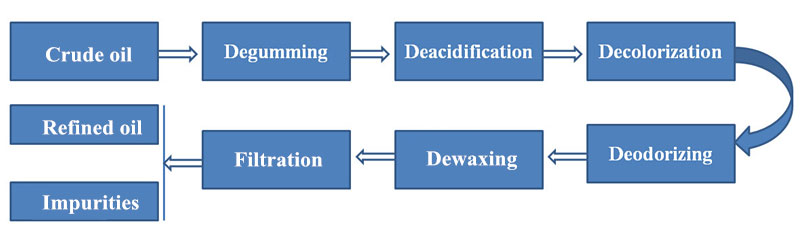

Oil refining is divided into physical methods, chemical methods and physical chemistry methods. For a certain crude oil, which methods should be used in the refining process, generally depends on the quality of crude oil, the application of refined oil, refining process budget and advanced nature of equipment, and both the refinery machine and entire oil refining line are available from us to do physical & chemical refining. The complete edible oil refining process mainly includes filtration, degumming, deacidification, vacuum dehydration, decolorization, deodorization, dewaxing and polishing filtration.

Please note: for self-employed entrepreneur and small-business owner, 1-10 tons/day batch type oil refinery production line is their best choice to refine crude oil into the first or second grade edible oil(e.g. peanut oil, rapeseed oil, tea seed oil, soybean oil, sunflower oil, etc.) with features of multi-purpose, easy transportation, small footprint, fewer operators and energy-saving.

Main Steps of Oil Mill Refinery

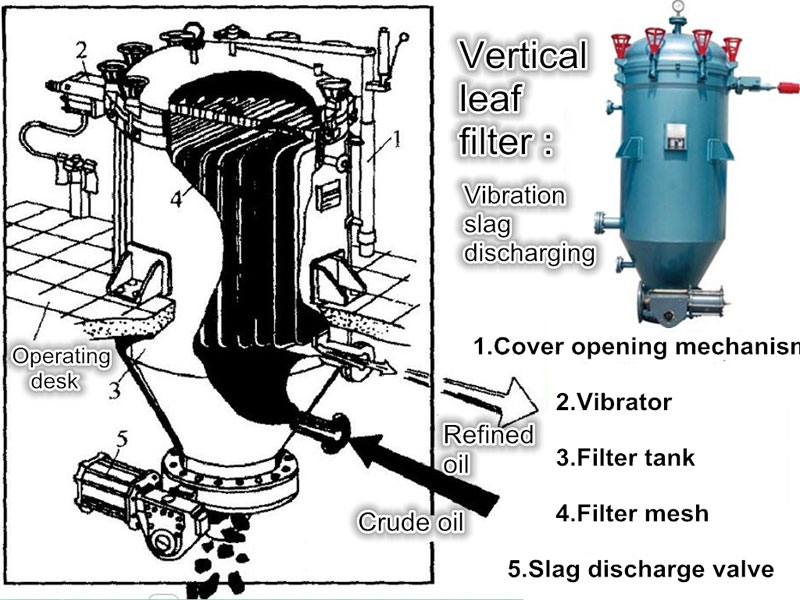

1. Filtration

The crude oil needs to be filtered at first to remove suspended particulate impurities and other mechanical impurities in order to carry out the further refining. By means of gravity, pressure, vacuum or centrifugal force, the method of filtering the crude oil through filter cloth is generally referred to as filtration.

Equipment

Vertical leaf filter (In order to ensure the continuity of filtration, it is recommended to install at least two filtration devices.)

2. Degumming

Whether physical refining or chemical refining, the first step is to remove phospholipids, sugar, protein and trace metals from the oil. Especially for physical refining, only by degumming to reduce the phospholipid content of raw oils within 0.015% can the oil be steam refined to produce high stability of the refined oil. Hydration degumming, a commonly used degumming method, is based on the principle of phospholipids dissolve in oil when in the anhydrous state, but after the hydrates formation with water, they would be precipitated out from the oil.

Operation Method

- Add water to the filtered oil, then heat and stir the mixture at a temperature of 35~50℃(Peanut oil, sunflower oil: 45~55℃; soybean oil, corn oil: 60~70℃). When most of the sedimentations precipitate, stop stirring and let stand for 2~3 hours to make the phospholipid completely precipitated, and then filter the phospholipid at the bottom.

- After degumming, the oil still contains 0.3%~0.6% moisture which would exacerbate the oxidation process (to increase the oxide in the oil) and the rapid rancidity and is not conducive to the storage of oil. The moisture could be removed in a vacuum dryer at the temperature of 100℃-105℃ and the vacuum degree is between 680-700mmHg. In addition, the phospholipid emulsion from hydration degumming contains the moisture content of 55~70% which can be dehydrated, so that it can not only concentrate the phospholipids but also to avoid phospholipids hydrolysis and fermentation. Moreover, the concentrated phospholipid has a higher flow consistency, and the application can be greatly broadened.

Equipment

Hydration tank, vacuum dryer

3. Deacidification

High acid value oil can't be stored for a long time, especially under the conditions of water and temperature, the oil is more susceptible to hydrolysis and rancidity. What's worse, some highly unsaturated glycerides would be oxidized into aldehydes, ketones and low molecular weight acids, emitting a disgusting smell and deteriorating the oil quality. Therefore, it is necessary to remove the free fatty acids in the oil. The neutralization process is an effective method to remove the FFA in the oil.

Operation Method

- For better quality oil, neutralization deacidifying should be applied to light alkali-high temperature method, that is, adding 8~12oBe(Baume degrees) of dilute lye to the oil at 85℃ initial temperature and 90℃ operating temperature. Light alkali will not saponify neutral oil even at the high temperature, and the large volume of light alkali can increase its chance of contacting with free fatty acids to completely remove the FFA. The separation of the soap foot is generally available by centrifugation.

- For poor quality oil, neutralization refining uses concentrated alkali-low temperature method, that is, adding 18~24oBe (Baume degrees) of the lye to the oil, then adjust the initial temperature at which is slightly 5 ℃ higher than the melting temperature of oil, and the final temperature is controlled at which is 5℃ higher than the initial temperature. When a large amount of soap foot are precipitated and separated by the centrifugal.

Equipment

Soap blending tank;

Oil and alkali proportioning device;

Mixing machine: ① blade mixer; ② centrifugal mixer; ③ static mixer.; Centrifuge: ① tube centrifuge; ② disc centrifuge

The deacidified oil contains a certain amount of water, which is susceptible to hydrolysis and rancidity and isn't conducive to the refining process. Drying is the necessary process to remove the water content in oil. Drying must be carried out under vacuum. It is recommended to dehydrate the oil at a residual pressure of 5.5-6.6 kPa (40-50 mmHg) at 90-95℃. This process not only removes the air in the oil to stabilize dehydration but also reduces dehydration loss and without waste generating. Vacuum dryer Some pigments such as chlorophyll and lutein can be saponified with alkali to form salts that can't be completely removed from the oil even after alkaline refining so that these pigments can coexist in the oil. In addition, gossypol can make the color of cotton oil brownish black. The presence of these pigments in oils deteriorate the quality of the oil and must be decolorized. The commonly used decoloration method is adsorption and with the help of the porous structure of adsorbent. The removal of the pigment is also carried out by utilizing the molecular force of adsorbent's surface due to the porous structure of the adsorbent. Intermittent decolorization process is now being applied by many oil processing companies, its operating essentials are rough: measure the oil and place it in the decolorization pot, heat the temperature to 90℃ in the vacuum 650~720mmHg, then 0.5~5% of activated clay is vacuum inhaled to the oil pot, stir the mixture and continue to heat up to the specified decolorization process temperature and maintain it at 20~30 minutes insulation decoloration; After that, the temperature is dropped back to 90~95℃ and the oil is get rid of the vacuum, and then pump the oil into the sealing machine for filtration. In order to achieve the best bleaching effect, decolorization of the oil should be through the bleaching test at first to determine the choice of adsorbent and its dosage and decolorization temperature, holding time and other technical parameters. Oil bleaching pot To process high-quality cooking oil, it is necessary to deodorize the oil to remove odorous substances and harmful chemicals so as to achieve a satisfactory flavor. Deodorization adopts that triglycerides and odor components have a different volatility to steam evaporate odor impurity from oil. Normal deodorization temperature is carried out at 200~274℃. First, it is the most basic process condition to use a modest amount of direct superheated steam and deodorize the oil above the oil temperature in the deodorizer. Second, deodorization should be under vacuum condition, which can not only effectively reduce the boiling point of the odor material but also rapidly increase the volume of the bubble, increase the working surface of the bubble, increase the evaporation coefficient and greatly shorten the deodorization time. Please note: if the intermittent deodorization pot is used together with the continuous deodorizing steam jet pump, not only the deodorization time can be shortened, but also the quality of the finished oil is more stable. Intermittent deodorization pot Wax has a high melting point, and it is easy to form a crystalline suspension in the oil, which will cause deterioration of oil transparency & oil quality. Therefore, dewaxing is a necessary process in the refining of oil. Dewaxing is the removal of wax crystals in the oil, it often adopts the freezing method, that is, freeze the oil first, and then filter and separate the waxing crystals & the mixture of polar substances precipitation by filtration. However, the freezing method can't remove all wax impurities and a small amount of suspended waxy crystals still remain in the oil. The viscosity of the oil is still high, which makes it difficult to separate the residues from oil. To enhance the waxy separation process, we recommend adding filter media (such as diatomaceous earth, perlite powder, etc.) during the separation to improve the residue on the filter screen. This will not only increase the efficiency of filtration but also promote the suspension of wax and oil separation. Since some of the wax has been precipitated in the vegetable oil, if direct crystallization, it will affect the entire process of wax precipitation and crystallization. Therefore, the oil should be heated firstly so that the waxy material can completely & evenly dissolve in oil. Next, freeze the oil in the crystallization tank at a certain cooling rate. In order to increase the aggregation collision between the precipitated wax particles and make the freezing evenly, proper stirring is required, and the appropriate stirring speed is 15 r/min. When reaching the crystallization temperature, stop stirring for maintaining a longer crystallization time, this process is called raising crystal, and its time period of 12-16 hours. Finally, separate the waxy crystals sediments from oil by a centrifugal. Plate heat exchanger, crystal tank, crystal maturing tank, centrifugal Finally, the oil is polishing filtered again through the fine filter for insurance, then the refined oil need be stored in sealed barrels in a dry, ventilated place under normal temperature. acid value×0.6 (physics refining) Crude oil is the unrefined grease which is obtained by pressing or leaching method. Its main component is a mixture of various triglycerides, commonly known as neutral oil. Due to the simple processing technology, crude oil has many impurities which are harmful to human health and it is easy to oxidize which isn't suitable for long-term storage. After chemical and physical refining, the impurities of oil are reduced to a certain standard, and the qualified oil products are obtained. The main impurities contained in crude oil are as follows: 2.1 Suspended impurities: such as sediment, slag cake, and other solid impurities. 2.2 Gum soluble impurities: mainly phospholipids. 2.3 Oil soluble impurities: mainly free fatty acids (FFA), pigments and so on. 2.4 Moisture 2.5 Other impurities like odorous impurities, waxy materials, trace metals and solvent. 3.1 The existence of suspended impurities, gum soluble impurities and moisture in oil would accelerate microbial activity, causing oil's hydrolysis rancidity. 3.2 The presence of phospholipids will give the oil a cloudy, dull appearance. What's more, the oil will produce a lot of foam when cooking. 3.3 High FFA content will increase oil odor, and some FFA would smoke when cooking. 3.4 Poor pigments deepen the oil color or even blacken the oil. Therefore, in order to manufacture qualified products that are accepted by consumers, it is necessary to refine the crude oil. Hydrolysis reaction: oil + water -> free fatty acids (FFA) Saponification reaction: oil + alkali -> soap stock Oxidation reaction: oil + oxygen -> peroxide According to the above three reactions, the improper storage of edible oil may lead to oil deterioration and even affect human health, so it's necessary to understand some storage knowledge of the vegetable oil. To sum up, there are four points of the oil storage: sealing, light proof, cryopreservation, and waterproofing. Therefore, after the oil tank is measured, the oil tank must be covered. The purpose is to prevent rainwater from dropping into the tank & resulting in the hydrolysis reaction of vegetable oil under suitable conditions, which produces excessive free fatty acids and causes deterioration of the quality and affects the quality of products. Color, free fatty acid (FFA), melting point & freezing point, soap, iodine value (IV), phosphorus content (PHOS), smell and taste.

Operation Method

Equipment

5. Decolorization

Operation Method

Equipment

6. Deodorization

Operation Method

Equipment

7. Dewaxing

Operation Method

Equipment

8. Filtration and Storage

Impurities Removed in Each Refinery Processing Step

Refining process

Removed impurities

Filtration

suspended particulate impurities and other mechanical impurities.

Degumming

phospholipids, sugar, protein and trace metals

Dewaxing

waxy crystals

Neutralization

free fatty acids, phospholipids, pigments

Decolorization

pigments, oxide, trace metals, waste clay, gum

Deodorization

free fatty acids, odorous substances

Polishing filtration

residual trace insoluble

Structure Features of Batch Type Oil Refining Production Line

Applications of 1~10T/D Oil Refining Equipment

Technical Parameters of Edible Oil Refining Plant

Production capacity

1~10T/D

Steam consumption

700Kg/T

Electric consumption

28Kwh/T

Water (soften water)

150Kg/T

Phosphoric acid

2~3 kg/T

Alkali

acid value×1-3kg/T

Circulating water cooling water yield

150M3/H

Bleaching earth consumption

3-5Kg/T

Waste bleaching earth oil content

≤25~35%

Refining losses

acid value×1.2 (chemical refining)

Bleaching losses

the quantity of bleaching earth×0.25%

Deodorization loss consumption

≤0.5%

Introduction of Edible Oil

1. Definition of Crude Oil

2. Impurities of Edible Oil

3. Reasons for Refining Crude Oil

4. Oil's Three Major Reactions and Storage Methods

5. Several Important Indicators to Measure Oil Quality