Small Edible Oil Extraction Machine

Small Edible Oil Extraction Machine Introduction

Small edible oil extraction equipment or tank extractor is a small scale batch type edible oil solvent extraction equipment. Tank extractor has both the function of extraction and meal desolventizing. It extracts oil by immersing the pre-pressed cake in solvent or miscella of various concentrations. The cake feeding, meal discharging, fresh solvent feeding and thick miscella discharging are all completed in batch.Usually, a battery of two or more extraction tanks is used to form a concentration gradient. The small oil extractor is an ideal edible oil extraction equipment for small-scale oil factory. The capacity of mini solvent extraction plant is 3 TPD, 5 TPD, and 10 TPD.

Advantages of Small Oil Extractor

1. Simple equipment, low investment, quick returns.

2. Less equipment, low power consumption, small land occupation.

3. The small oil extractor has low solvent consumption.

4. Having strong adaptability, suitable for specialty and high-value oils.

5. Having steam stripping function, no need for desolventizer-toaster.

Application of Edible Oil Extraction Tank

The small oil extractor is suitable for small-scale edible oil plant. It can be used for extracting oil from the pre-pressed cake of various oilseeds such as rapeseed, sunflower seed, peanut, soybean, rice bran, cottonseed, camellia seed, etc.

Structure of Edible Oil Tank Extractor

Small Edible Oil Extraction Machine consists of tank body, transmission part, stirring apparatus, meal discharge part and balancing device, etc.

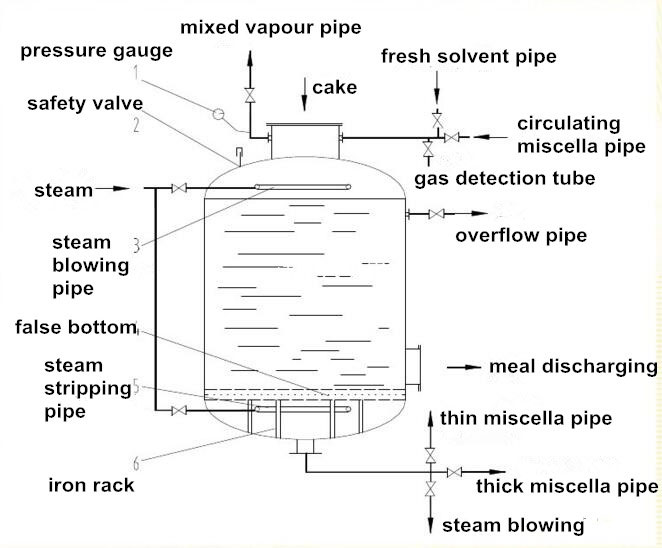

Tank Body

The top of the tank is cone shape. On the upper head, there are feed pipe, miscella/solvent inlet pipe, steam blowing pipe, blow-down pipe, overflow pipe, pressure gauge, explosion-proof valve nozzle, etc. On the cone at the tank bottom, there are miscella outlet pipe, steam stripping pipe, etc.

Transmission part

The transmission part is on the top of the extraction tank. Adopt 2-speed drive with belt pulley and worm gear.

Stirring apparatus

The stirring apparatus is used to remove the extracted meal during solvent stripping. On the spindle, there are two layers of the single-arm stirring blade.

Meal discharge door

Meal discharge door is at the bottom of the extraction tank and is reversal.

Working Process of Mini Solvent Extraction Plant

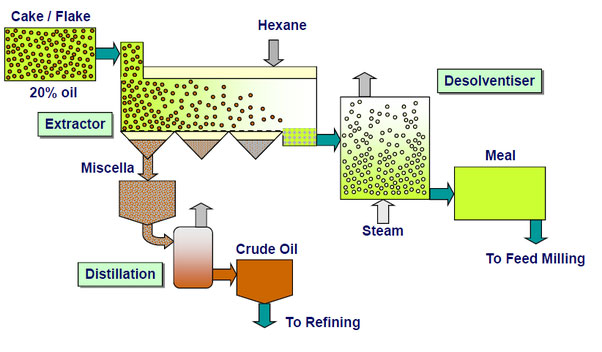

The process of this mini solvent extraction plant includes cake loading, extraction, steam blowing, steam stripping and meal discharging.

1. Through the screw conveyor, the pre-pressed cake from the pre-pressing workshop is sent to the extraction workshop. Through the bucket elevator, the cake is lifted to the overhead screw elevator and enters the extraction tank. Or the cake enters the buffer bin separately and then enters the extraction tank concentratedly to shorten loading time.

2. After loading, seal and close the cover tightly.

3. Open the solvent pump and various valves and pump out the fresh solvent from the solvent holding tank. Open the steam valve and enable the temperature of the solvent rises in the solvent pre-heater. When the temperature reaches 45-50℃, the solvent enters the tank extractor through the spraying pipe. The height of the solvent should exceed the level of the cake for 20-50 mm. Open the solvent-carrying air valve for normal immersion.

4. After immersed for 40-60 minutes, pump the miscella into the temporary storage tank or miscella treatment system, and then pump fresh solvent into the extraction tank to immerse again for 40 minutes. Pump the miscella into the next extraction tank. Replenish with fresh solvent if the miscella is inadequate.

5. After steam blowing and steam stripping, the remaining solvent is removed from the wet meal, and then the meal is discharged through the meal discharge door.