Shea Butter Oil Extraction Machine

Shea butter has three colors: ivory, beige and yellow. The darker the color, the better the effect. More than 90% of shea butter is supplied to the world's major cosmetics companies, such as international famous cosmetics companies L‘Oreal Paris, Doublebaby, DHC, The Body Shop, Swiss Legend, etc.

In countries where shea tree is planted, setting up an oil mill plant to produce high quality shea butter would be profitable since the high value of shea butter and its wide applications in cosmetics, food, medicine and etc. Our Company has developed into one of the largest cooking oil press machine supplier. For shea butter extraction, we provide different oil extraction technologies and equipment to meet different requirements. If you are interested in shea butter oil processing, here is what you need.

Low Temperature Shea Butter Oil Extraction – Hydraulic Oil Press

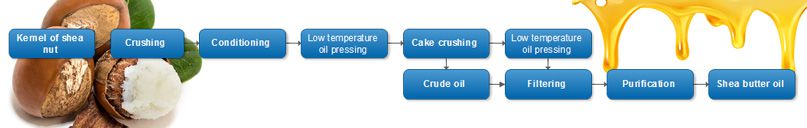

Hydraulic oil press machine has many features, like simple structure, high quality oil cake, less energy consumption, so it has been widely used to process shea butter. The main equipment for shea butter oil extraction plant by hydraulic oil press: conveyor, crushing machine, conditioning machine, hydraulic oil press, cake crusher, plate and frame oil filter, etc. If you are interested in buying the hydraulic oil press machine for your shea butter oil processing business, just contact us directly to get the machine parameters and price list!

The Shea Butter Oil Extraction Process

- The fine particle powder (35 ~ 40 mesh) of crushed kernel was tempered (60℃ ~ 70℃) to adjust the squeezed moiture not more than 5%. Then, the flaked cake (5 ~ 7kg for each flaked) was pressed for the first time (pressure 40 ~ 50mpa, temperature 60℃ ~ 70℃), and the residual oil of the virgin flaked cake was 28% ~ 32%.

- According to the above process requirements, the virgin cake was broken, tempered and repressed, and the residual oil of the repressed cake was 18% ~ 23%. Repeat for the third and fourth time to press, the final pressed cake residual oil 10% ~ 13%.

-

- The shea butter (impurity) is obtained from the low temperature hydraulic press after heat preservation and precipitation and then filtered at 60℃ ~ 70℃. It can be seen from the process of hydraulic pressing that the oil is relatively clear, the crude oil is of light color, the crude oil is of good quality after rough filtration, the acid value, peroxide value and other indicators meet the requirements, the cake color is also relatively light and there is no sign of deepening.

- Therefore, the subsequent physical refining only needs to carry on the fine filtration and the fine filtration under the heat preservation state of 60℃ ~ 70℃ to obtain the finished product refined shea butter.

Shea butter oil extraction technology – factory price shea butter oil extraction machine for high quality shea butter oil making: buy shea butter oil extraction machine from oil mill machinery manufacturer or supplier at factory price, get FREE technical instruction of shea butter oil production process and business plan to set up shea butter oil extraction plant project in Uganda, Guinea, Senegal and Nigeria, etc., at low cost.

Screw Oil Pressing For Shea Butter

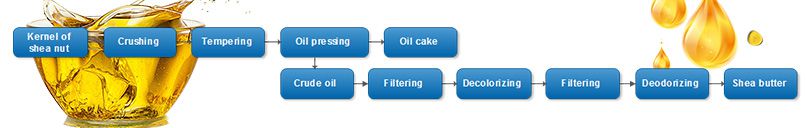

Screw oil pressing is the most widely used vegetable oil extraction method. It also can be used to extract shea butter oil from the shea nut. The advantage of shea butter oil extraction technology by screw pressing method has large production capacity, high oil output, and continuous oil production. However, the color of oil and oil cake is deep and too many impurities in the oil, so, it requires oil refining process.

Shea Butter Oil Pressing And Refining Process

Shea Nuts Oil Expeller machine

Firstly the shea nut is subjected to mechanical extraction with the help of screw presses. The resultant cake containing 14 to 16% oil (butter) then is subjected to solvent extraction process. Apart from that, The shea nut preparation required is cooking and flaking purpose.

Briefly speaking, the main procetures in the shea nut solvent extraction plant including the following: they are Seed Cleaning, Cooking / Conditioning, Expelling and Solvent Extraction.

The processing of shea, in general, involves many activities that start soon after wild-harvesting, through refining to manufacturing. The major processes involve: curing, extraction, refining, fractionation and manufacturing.

Shea Butter Refining Plant

After the extraction of the crude shea butter, also known as ”natural shea butter” or “ bulk shea butter”, there are various options for modifying or cleaning loosely described as refining. Every stage of refining takes natural ingredients, usually deemed unfit for human consumption, out of the butter.

The process then introduces harmful refining chemicals as catalysts, which have to be removed at the end of the process by “re-refining”.Traditional and organic forms of processing hold an important market niche for the ever-increasing demand for pristine natural products. The four major processes for modifying or cleaning crude shea butter are: De-gumming, Neutralization, Bleaching, and Deodorization.

Shea Butter Fractionation Plant

Shea butter has two main components – the stearin (the creamy fat) and the olein (the runny oil). The production of cosmetics mainly uses olein, while the stearin goes into margarines and chocolates. The process which separates the two components is “fractionation”.

Two methods of fractionation exist – the chemical/mechanical method and physical method. The former requires the creation of a vacuum (airless condition) and applies a chemical reagent to separate the olein from the stearin at different temperatures. After separation, the oily part can then be poured out through decantation or siphoning.

The physical process involves a process of sedimentation or a centrifugal method to cause the stearin to separate from the olein. This process, however, proves more difficult when working with the West African shea butter because of the higher ratio of stearin to olein.

Shea Nut Production In Africa

| Country | Production |

|---|---|

| Nigeria | 361,017 tons |

| Mali | 75,000 tons |

| Burkina Faso | 45,183 tons |

| Ghana | 33,878 tons |

| Cote d'lvoire | 31,492 tons |

| Benin | 14,366 tons |