Setup a Complete Cooking Oil Production Plant

How to Setup a Complete Cooking Oil Production Plant?

Starting up a cooking oil mill plant can seem like a lot of work, but it's actually very easy once you have your cooking oil production business plan. There are just some simple steps that you need to take in order to successfully operate a oil mill plant.

Get Customized Business Plan

First of all, make sure that you've got your plan in the right direction.You can ask for advice from a professional on the matter, because they can point you in the right direction through the design process. Customized plans are more appropriate to your situation and less likely to go wrong. (Related post: Oil Extraction Business Plan >>)

Find Right Supplier and Buy Required Equipment

Once you get your plans in place, then you can looking for the manufacturer or supplier from the local market or the international market. A reliable supplier can help you choose the right cooking oil production equipment and setup the factory to unnecessary spending and lower the investment cost. (Read more: Oil Mill Project Cost >>)

Establish Market Strategy for Your Cooking Oil

The market competition of cooking oil is very fierce all the time. In addition to ensure the high quality of products, reasonable marketing strategy can help you gain customers faster, build your own brand and expand the sales.

Above is some of information on starting cooking oil production line. It is not difficult, but still requires complete plan. Maybe some of you have know how to start their cooking oil production business, and what they want to know mostly is the full set of equipment for a complete cooking oil production plant and what is cost of investment?

Advantage:

- Stable performance. Composed of high-quality carbon steel which is robust and strong enough to bear wearings and tearings, suitable to ceaselessly oil pressing.

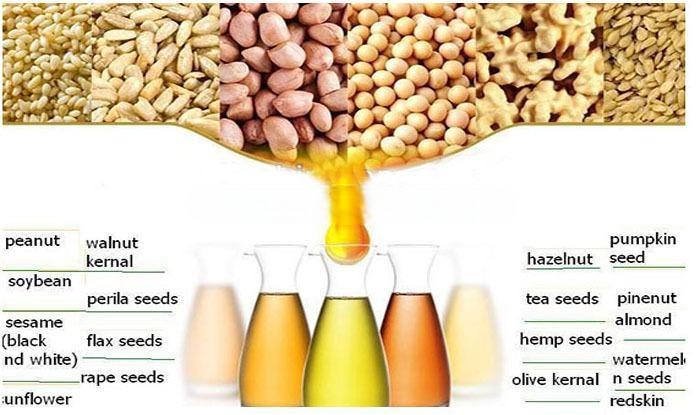

-Widely used for pressing various oil seeds such as peanut, soybean, sesame, flax seed, cottonseed, sunflower, etc; welcomed by medium and large size cooking oil mills and plants

- With the proper-designed pressing chamber, the pre-heating process and rotation of the machine quickly increase the temperature in the chamber, which speeds up oil seeds inner structure breaking and pressed easily.

-Save labor and energy. 60% electric power and 40% labor can be saved based on the same oil output.

- Optional accessories for choice

1. There is less than 6% oil in the cake;

2. The thickness of cake can be adjusted when machine stops running;

3. Only needs 10-20 square meters workshop for the oil pressing .

4. The surface of the oil machine is made of chrome plated stainless steel.

5. High efficiency, energy and labor saving, easy operation, simple maintenance.

Specification

| Model | Power | Capacity | Dimension |

| LHLX-60 | 2.2 KW | 30-60kg per hour | 1200*780*1100mm |

| LHLX-70 | 3 KW | 50-80kg per hour | 1400*8600*1260mm |

| LHLX-80 | 5.5 KW | 65-130kg per hour | 1700*1200*1500mm |

| LHLX-100 | 7.5KW | 140-200kg per hour | 1800*1300*1600mm |

| LHLX-125 | 15KW | 180-250kg per hour | 2100*1400*1700mm |

Service:1.Design according to your special requirement. 2.Free repair within 1 year.

3.Engineer could work to your country

4.we are responsible for installation, test running and training local workers for you.