MAXIMIZE YOUR SUNFLOWER OIL EXTRACTION YIELD WITH OUR MACHINES IN ZAMBIA

Sunflower Oil Press Machine Zambia

Our Company has various types of sunflower oil press machines that are great for South Africa market.We mainly has four types sunflower oil expeller machine: single screw oil press, small oil press machine with heating system, automatic oil extraction with vacuum filters, automatic oil making machine with air pressure filters. Below is the main pictures of our sunflower oil machine types. If you are interested in any one, please contact us to get the latest price list.

Main Technical Parameters of Sunflower Oil Machine

| Sunflower Oil Machine Type | Capacity | Power | Color | Remark |

|---|---|---|---|---|

| Single Screw Oil Press | 60-850KG/H | 5.5-30KW | Blue or Customized | / |

| Screw Oil Press with Heating System | 60-500KG/H | 5.5-4P-18.5-6P | Blue, Silver or Customized | with heating System |

| Automatic Oil Press with Air Press Filters | 150-500KG/H | 13.6-23.9KW | Silver or Customized | with air pressure oil filter and heating system |

| Automatic Oil Press with Vacuum Filters | 150-500KG/H | 13.6-23.9KW | Silver or Customized | with oil vacuum filter and heating system |

The sunflower oil machine has many favorable features. It is compact in design, efficient in oil pressing, convenient in maintenance and operation. Most importantly, it can be also used to process a very wide range of oil-bearing seeds and oil-rich plants, such as peanut/groundnut, palm kernel, rice bran, cottonseeds, soybeans, copra, sunflower seeds, corn germ and more.

For customers from Zambia, we offers the most cheap factory price to help you buy the high quality sunflower oil machine. And every year, we will have engineers and sales to Zambia to visit our customers and help them solve problems they are encountered.

Sunflower Oil Processing Steps

Sunflower oil processing technology is generally divided into two types, physical pressing and solvent extraction. The Small Oil Production Line adopts direct pressing method, and sunflower seed oil press is used for pressing, and the obtained sunflower seed oil is filtered or refined for sale. Sunflower seed oil is usually prepared by prepressing and then solvent extraction in Large Sunflower Oil Factory. Below details the production process in small scale sunflower oil processing plant by physical pressing for your reference.

- Cleaning: Selected sunflower seeds are cleaned or magnetic separated to remove the clods, stalks, leaves, and other impurities.

- Husking: Husking is to improve the oil output and the quality of oilcake, at the same time, reduce wear and tear on oil press machine.

- Flaking: Flaking is to increase the contact area between equipment and oilseeds, which will improve the effect of steaming or cooking and futher to improve the oil yield.

- Steaming or Cooking: Steaming or cooking is to regulate the moisture and temperature of the embryo and finally improve the oil output.

- Oil Pressing: Pressing is the process to squeeze oil out from the raw materials.

- Oil Filtration: Crude sunflower oil is usually filtered to remove the oganic impurities.

- Oil Refining: Most sunflower oil manufacturing plant will have oil refining machine to remove the unhealthy substance in the sunflower oil. We also provide efficient and customized Sunflower Oil Refinery Machine at wholesaling price.

How To Start Cooking Oil Manufacturing Business In Zambia?

Some of the steps to start a cooking oil production business in Zambia are as follows:

- Examine the Market

It is critical to research the demand for cooking oil in various parts of Zambia, as it is heavily influenced by income and population density. The common hot sale cooking oils has soybean oil, sunflower oil, coconut oil, palm oil, palm kernel oil, etc.

- Developing a Business Project Report

A business project report must also be prepared in order to obtain financing from banks and other financial institutions. Financial and technical analysis must be included in the report. The technical analysis must include manufacturing technologies, plant capacity, raw materials to be used, and the overall organization's production process. The business objectives must be stated clearly, and attention must be paid to the financial aspects of the business, which include working capital, fixed costs, expected sales revenue, and ROI. (Related article: Adjustable Screw Cold Press Sunflower Oil Press in Uganda >>)

- Make the Financial Arrangements

If the cooking oil business cannot be started with self-owned funds, funds can be obtained from banks or local venture capital firms to start such a business.

- Choose A Location

To begin a cooking oil making business, it is necessary to look for a suitable location for the establishment of a profitable enterprise. Cooking oil does not require much storage space.

- Determine the Oil Production Process

There are numerous edible oil production processes available on the market today to maximize oil extraction from various oil seeds. If the oil content of the oil seeds is high, mechanical pressing will extract approximately 85% of the oil. To extract the majority of it, the solvent extraction method for oil cake residual must be used. One must select an oil production process that meets the needs of the business. Welcome to contact us to get the max oil yield of different oil seeds!

- Buying Cooking Oil Processing Machinery

The main requirement in the cooking oil business is machinery. There are numerous oil mill machinery suppliers in the world that provide oil extraction machinery. A thorough investigation must be conducted in order to select the most dependable company from which to purchase the cooking oil manufacturing machine.

- Install Machinery and Establish a Cooking Oil Plant.

After purchasing the cooking oil processing machinery, install it and complete the cooking oil business setup. The supplier of cooking oil machinery will install the machinery, and the cooking oil plant will be built.

- Obtaining Raw Materials

It is critical to find a consistent source of raw materials for the business. As a result, the company must identify a source from which raw materials can be obtained on a regular basis.

- Business Registration

In Zambia, registering a cooking oil business is required. The business is granted a trade license once the registration is completed. A bank account must be opened to conduct the necessary transactions.

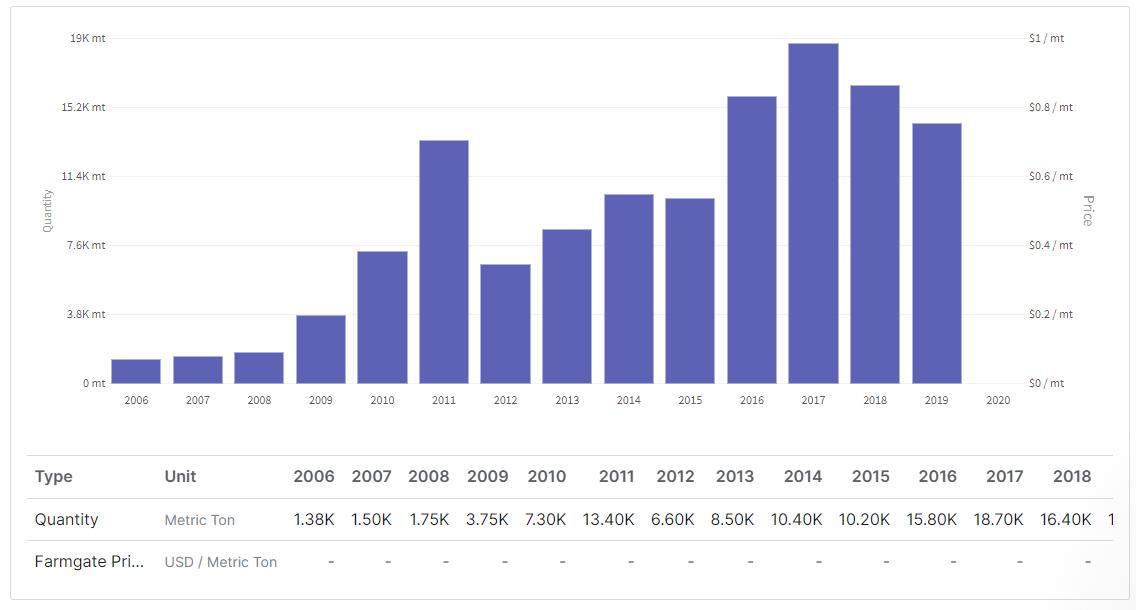

Production of Refined Sunflower Oil in Zambia

Discover production data of Refined Sunflower Oil in Zambia. Get production volume, price data, trends, and more. The information below is based on the FAO code 0268 (Oil, sunflower).

Sunflower Seeds & Sunflower Oil In Zambia

Sunflower seeds are extremely nutritional seeds packed with vitamins, protein, fibers and some of the essential minerals, as well as healthy fats. Sunflower seeds are commonly harvested for being snacks or the production of sunflower oil and cake oil. Zambia is the tenth largest producer of sunflower seeds in the world. The sunflower oil industry is one important economic sector in the country and even with some problems, which will be discussed later, South Africa remains an important importer for both sunflower oil and oilcake. About Sunflower Oil Manufacturing Cost, please contact us to get free quotation.

Lately, the Zambia industry for these nutritious seeds has been pretty volatile in terms of production, while the demand for vegetable oil has increased by almost 40%. The volatility experienced by the production of sunflower seed caused visible fluctuation in the volumes produced. After a few years of ups and downs, lately, production in Zambia has been increasing. Zambia is a major exporter of the seeds for countries like Kenya, Namibia, Uganda, Botswana, and Pakistan. The largest factories for sunflower seeds in Zambia can be found in Lusaka and Ndola provinces. Zambian domestic production is stable enough to be able to accommodate the local demand, thus most of the sunflower seeds products consumed in the country are produced locally.