Complete Set of Palm Oil Processing Machines, 1-5 tph

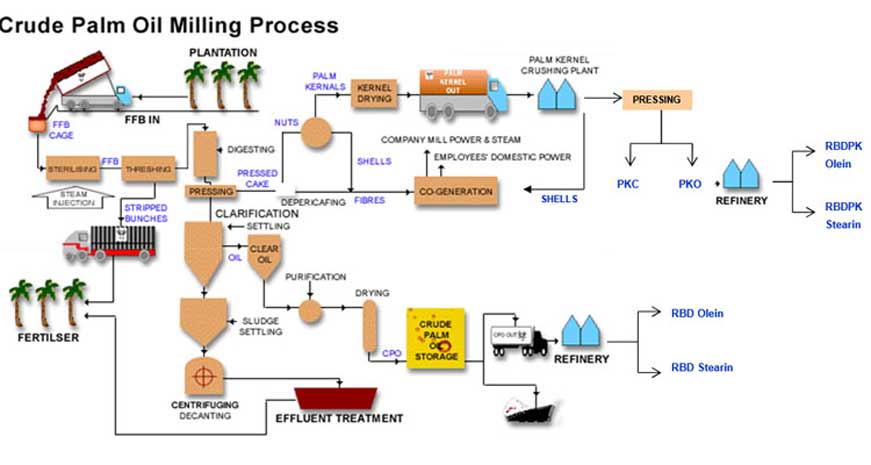

Complete process flow chart of palm oil processing machines, complete set from 1 to 5 tph:

Main section and main machines of the complete set of 1-5 tph palm oil processing machines:

| NO. | Main section | Main device | The functions |

| 1 | Reception section for bunches of fresh palm fruit | The loading ramp | Weighing the bunches of palm fruit |

| 2 | Sterilization section | Sterilization machine | reduce enzyme activity, prevent rancidity |

| 3 | Threshing section | Thresher | separate the empty fruit clusters and the palm fruits |

| 4 | Pressing section | Screw presser | Squeeze out most of the palm oil mechanically |

| 5 | Oil clarification section | Clarification tank | Filter impurities in crude palm oil |

| 6 | Fiber separation section | Palm kernel and fiber separation machine | separate the palm nuts from the fibers |

| 7 | Palm kernel recovery section | Palm kernel and shell cracking and separation machine | Cracking palm nuts to obtain pure palm kernel |

| 8 | The engine room | Diesel generator | power supply for palm oil mill |

| 9 | Boiler room | Boiler | Providing steam for an entire palm oil mill |

Equipment directly related to 1-5tph palm oil processing machines

Palm fruit receiving station:

Used to load palm fruit brunch from plantation, transport to sterilizer. The receiving station adopts steel structure and concrete structure. Save on equipment costs and construction costs. Have hydraulic control system, automatic opening/stop of hydraulic door for continuous operation. Reduce the number of operators, work more smoothly and improve work efficiency.

Palm fruit sterilization station:

In the small-scale palm oil extraction process, a vertical palm fruit sterilizer is used. The vertical palm fruit sterilizer uses direct steam to treat palm fruits, which can reduce enzyme activity, prevent rancidity, and ensure good crude oil quality. At the same time, it is beneficial for the threshing process.

Palm fruit threshing station:

The palm fruit thresher is used to separate the empty fruit bunches and palm fruits. According to the different production scales of the palm oil mill plant, we can provide different types of palm fruit thresher to meet the production needs, such as: single-type palm fruit thresher and drum palm fruit thresher. In the current palm oil production process, we usually have a spare one, in case one of them fails to work. After the sterilization process is completed, the sterilized palm fruits will be transported to the next station. The empty fruit bunches from the palm fruit thresher will be transported outside and can be used as fuel for the palm oil mill.

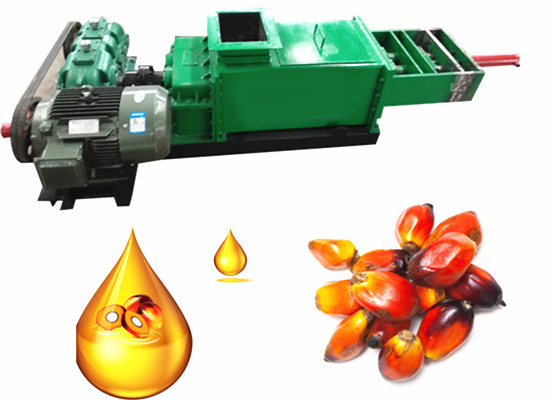

Palm fruit digestion and pressing station:

The pressing station in 1-5 tph new technology palm oil processing machines includes digester and oil presser.

The sterilized palm fruits will be transported to the palm fruit digester. There are blades in the digester, the blades will be rolled by the motor which is located at the top of the digester. The skin of the palm fruits can be crushed by blades, in addition we will fill steam in the digester for heating. The cells of the palm fruit pulp can be destroyed under high temperature conditions, after which the palm pulp will be sent to a twin-screw palm oil press to extract most of the palm oil.

Crude palm oil clarification station:

A mixture of oil, water, and solids from the bunch fibers is conveyed from the palm oil digestion and pressing station to a clarification tank in the palm oil mill machinery. In the conventional process, separation of the oil from the remaining liquor is achieved by gravity-based settling tanks. The mixture containing the crude oil is diluted with hot water to reduce its viscosity. A vibrating screen is used to remove some of the solids. The oil mixture is heated to 85-90°C and allowed to separate in the clarification tank. A settling time of 1 to 3 hours is acceptable. The top oil is skimmed and purified in the centrifuge before being dried in a vacuum dryer. The final crude palm oil is then cooled and stored. The bottom layer of the clarification tank is sent to the centrifugal separator where the remaining oil is recovered. The oil is dried in vacuum dryers, cooled and sent to storage tanks.

Related reading: Setting Up a Small Palm Oil Mill Plant

Crude palm oil production quality index:

| 1,transparency : | clear and transparent. |

| 2,smell and taste : | no strange smell; |

| 3, color (Lovibond 133.4-place colorimeter) | ≤ R1Y10; |

| 4,moisture and volatile matter: | ≤ 0.10%; |

| 5,impurities content : | ≤ 0.10%; |

| 6,acid value (mgKOH/g) : | ≤ 0.12; |

| 7,peroxide value (mmol/kg): | ≤ 3. |

Our professional engineers can help you design and install palm oil processing machines according to your capacity and requirements. If you want to set up a palm oil mill in Nigeria, Malaysia, Indonesia or other countries, just tell me your production capacity and budget, our engineers will design suitable palm oil processing solutions for you.