6yl Screw Oil Presser/Sunflower Oil Press Mill Machinery in Ethiopia

6YL series screw oil press machine boasts strong pressing structure and automatic heating system for highest oil output. Different from traditional small oil screw press, 6YL adds an automatic heater to increase the oil output rate by hot extrusion. This automatic oil press machine is ideal for vegetable oil making, from small oil pressing workshops to large-scale oil extrusion factory.

Main advantage of screw oil press machine:

1. High oil yield, small space occupied and low expense on equipment and electriciy.

2. Multi-functional used for pressing various of oil crops.

3. Simple operation and stable production performance.

4. Various machine models for options according to the capacity.

5. Widely used by small workshop and factories and hot selling at home and abroad.

Screw Oil Presser Working principle:

When the oil press is running, the processed material embryo enters the squeezing chamber from the hopper. The helix of the squeezed screw is pushed in and squeezed. The material embryo is carried out in the pressing chamber of the oil press. Under the condition of high pressure, there is a great friction resistance between the material embryo and the squeezing and squeezing chamber. The heat caused by the heat caused the thermal denaturation of the protein in the embryo, destroyed the colloid, increased the plasticity, and also reduced the viscosity of the oil and thus precipitated oil easily. The oil production rate of the oil press is improved.(See more: Factory Supplier

When the oil press is running, the processed material embryo enters the squeezing chamber from the hopper. The helix of the squeezed screw is pushed in and squeezed. The material embryo is carried out in the pressing chamber of the oil press. Under the condition of high pressure, there is a great friction resistance between the material embryo and the squeezing and squeezing chamber. The heat caused by the heat caused the thermal denaturation of the protein in the embryo, destroyed the colloid, increased the plasticity, and also reduced the viscosity of the oil and thus precipitated oil easily. The oil production rate of the oil press is improved. (See more: Factory Supplier Peanut Black Seed Flaxseed Sunflower Oil Press Machine With Filters>>)

Main Steps of Making Sunflower Oil:

(1) Seed Cleaning: It is the first step to help ensure that a quality oil and meal are obtained. Aspiration,indent cleaning, sieving, or some combination of these are used in the cleaning process. During processing,meal quality can be affected by temperature and other factors.

(2)Pre-conditioning and Flaking: The cleaned seed is first heated to about 30-40ºC to prevent shattering. Some moisture adjustment may also be required. The preheated seed is then flaked on roller mills, set to very tight clearance.

(3) Cooking:The flaked seeds are then heated to about 75-100ºC in cookers. An important function of the cooking operation is to control enzymatic activity in the flaked seed, which depends on temperature and moisture content.

(4) Pressing: The heat-conditioned seed is passed into continuous sunflower screw oil press machine or expellers to reduce the oil content of the seed from about 42% (8% moisture basis) to 16-20% mechanically.

(5) Refining: To ensure good stability and shelf-life, the crude oil goes through a series of refining processes to remove compounds like phospholipids, mucilaginous gums, free fatty acids, colour pigments and fine meal particles.

Product Details

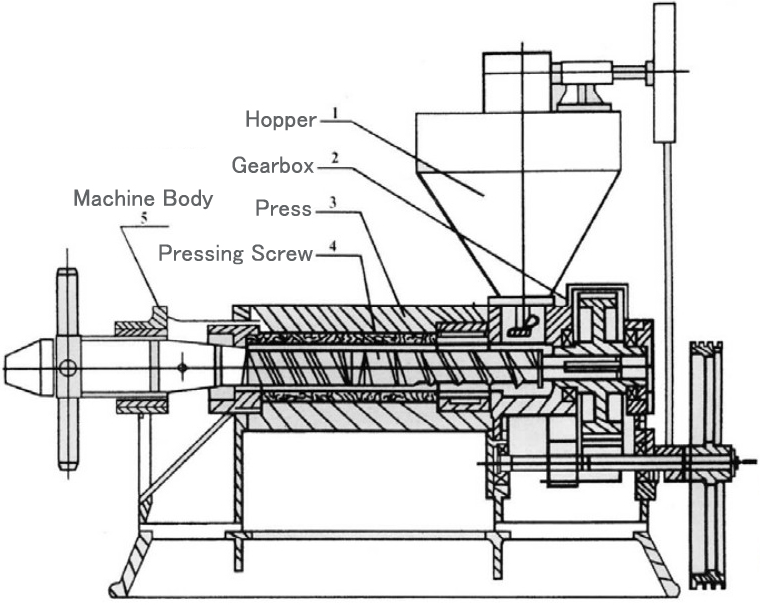

Main parts of oil press machine

Name: Gear box

It is composed of gear box, cover, cyclinder gear, driving axis, rolling bearing and triangle belt wheel, etc. Oil can be added when the oil adding screw on top of the gear box is discharged. Likewise, oil can be released when the oil release screw on the bottom removed.

Machine parts

Name: oil cake discharge structure.

The discharge structure of oil cake, which is hard and corrosion resistance.

Machine Parts

Name: Screw axis

It is composed of screw axis, pressing screw, cake guide ring, press nut, adjusting bolt and planar bearing, etc.

Other details display

Product Parameters

| Model | Capacity | Power(W) | Voltage | Packing size | Gross weight and net weight (KG) |

| 6YL-68 | 40-50Kg/h | 5.5KW | 380V/50HZ/Triple phase | 880*440*770 | 160/140 |

| 6YL-80 | 80-150Kg/h | 5.5KW | 380V/50HZ/Triple phase | 1510*440*700 | 350/330 |

| 6YL-95/100 | 150-200Kg/h | 7.5KW | 380V/50HZ/Triple phase | 1910*550*765 | 450/420 |

| 6YL-120 | 200-300Kg/h | 11KW | 380V/50HZ/Triple phase | 2100*630*770 | 530/500 |

| 6YL-130 | 300-400Kg/h | 15KW | 380V/50HZ/Triple phase | 2280*700*780 | 780/750 |

| 6YL-160 | 400-600Kg/h | 18.5KW | 380V/50HZ/Triple phase | 2050*600*850 | 950/900 |

Applications

Although 6YL Screw oil press machine is small in size, it boasts superior oil making capacity.It can be used for various materials such as Peanuts, Rape seeds, Sesame seeds, Soybeans, cottonseeds, Tea seeds, Tung Tree seeds, Sunflower seeds, Palm kernel, Coconut meat, Corn germ, Rice bran, Almonds, Black cumin, Cacao beans, Coffee beans, Hazelnuts, Hemp seed, Jatropha, Jojoba, Linseed, Mustard seeds, Black seeds, Palm nuts, Poppy seeds, Pumpkin seeds, Shea nuts, Walnuts,etc.

Packing & Delivery

| Packing | ||

| Size | To be determined | |

| Weight | Depend on different capacity equipment | |

| Packaging Details | The normal package is wooden box. If export to European countries, the wooden box will be fumigated.If container is too weight, we will use per film for packing or pack it according to customers special request. | |

| Delivery | ||

| Tool | Ship, express or Air | |

| Packing | In containers | |

| Shipping Details | The normal shipping method is by sea. We also accept Air Transporting if you are in urgent need. You can contact your own shipping agent or ask us to arrange shipping for you. |

|

FAQ

Q1: What is the Warranty for the machines?

A1: 12 months free guanantee and life long standard paid service.

Q2: What is the Material?

A2: Carbon steel suitable for pressing.

Q3: When can I get the price?

A3: Within 24 hours, if urgent, please directly call us.

Q4: Whether the machine price can be more discount?

A4: In general, our MOQ is 1set with very reasonable price, but if large order, we also can apply to our manager to appropriately give you a little discount.

Q5: How long will it take to receive my products?

A5: Generally, it will take about 5 days to make the machinery, 3-7 days to deliver it to

shipping port, and 10-45 days on sea transporting.

Q6: Is the machine suitable for different raw material ?

A6: Yes, but we recommend no more than 3 different types.